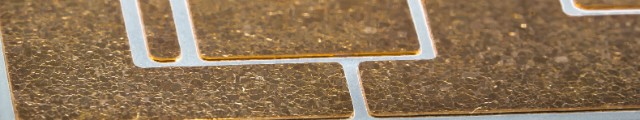

Copper for copper-ceramic substrates

Aurubis offers world leading solutions for different substrates in existing and future markets. By comprehensive technical services, geared entirely to the needs of our customers we provide customer-specific solutions.

The range of products offers the best solutions for different applications, e.g.:

- Direct-Copper-Bonding (DCB) with Al2O3, AIN or Si3N4 ceramics

- Active-Metal-Brazing (AMB) and Thermal Diffusion Bonding with Si3N4 or AlN ceramics

- New R&D projects with new ceramics

Aurubis' dedicated copper solutions fulfill the special requirements of the high temperature bonding and brazing solutions.

Solutions designed for diverse working environments and special customer needs

Specially designed high-conductivity products offer unique properties that makes Aurubis preferred partner as the producer for substrate copper. Our products offer stable and high quality and reliability in the assembly of the Power Modules. Our different solutions are designed for different working environments and for different customer needs. All our special products are designed to pass all the requested life-time tests and other approval stages.

Facts & Figures

Designed products for substrates

>

Amount of different ceramics and resins

>

Research and Development

>

We are offering mass production batches with stable and high quality. Also small batches are available for R&D purposes and in approval stage in different dimensions. Continuous business development with multiple key stakeholders in the business is the foundation of our preferred solutions in the market. We are pleased to develop our offering even further with our existing and new customers and partner network.

Copper for other copper-insulator substrates

New and current technologies are developing, and they can be used in different final environments with higher and higher voltages. Development of dielectric materials (resin/polymer/ceramic) has created more opportunities for example to Insulated Metal Substrates (IMS). IMS can today be used with higher voltage applications than before. Copper as a base layer is then preferred material due to increased thermal demand.

Aurubis offers different solutions and alloys to fulfill all the demands of base layer and circuit layer material. Unlike high temperature brazing/bonding substrates, the IMS is performing in the best way with different Aurubis alloys. Final choice is then considered together with the customer, depending on required properties.

Mainly but not only C1020 OF-copper is typically the preferred solution with high thermal and electrical conductivity for both circuit pattern side as well as for base plate side. Other alloys are used as well and are subject to customer specific demands.

Aurubis has different solutions to achieve increased adhesion behaviour between the resin and the copper. Aurubis is continuously working with existing and new partner network to supply copper with best possible mechanical properties and surfaces. We are pleased to work and develop with new partner companies to create best possible copper products for rapidly changing markets.

Downloads

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Aurubis DCB and AMB solutions

PDF

2 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Product Brochure Rolled Products

PDF

6 MB

Helge Lehmann

Sales Director

| Phone | +49 2402 1241 2124 |

| Mobile | +49 15201512374 |

Juuso Järvinen

Senior Sales Manager, Global Power Electronics

| Phone | +358 44 726 7899 |