Environmental protection at Aurubis Italia, Avellino site

Aurubis Italia, the only copper rod producer in southern Italy, is located in Avellino. In 2023, a total of around 90 employees produced about 180,000 t of rod and about 2,500 t of wire for special applications.

Aurubis Italia has had an IPPC permit since 2009 (IPPC refers to the EU Directive on Integrated Pollution Prevention and Control). The high efficiency of Aurubis Italia’s production lines enables nearly 100 % of the raw materials used to be processed into products.

Modern cleaning and filter facilities keep off-gas and wastewater to a minimum. Wastewater is continuously monitored before being released into the sewer system thanks to an automatic water sampling system. A street sweeper cleans the roads and yards at the Avellino site, which has reduced the metal load in the discharged water.

Volatile organic compounds (VOCs) from the rolling mill were significantly reduced by lowering the use of isopropyl alcohol. The VOCs are collected and treated with a scrubber system. The fugitive emissions in the smelting area were considerably reduced due to a vacuum system and hoods on the launders and holding furnace. Dust emissions and persistent organic pollutants (POPs) from the shaft furnace have been drastically reduced. Many small energy-saving initiatives have been implemented during the last few years thanks to continuous improvements in the production process.

Aurubis Italia successfully completed the EMAS registration (Eco-Management and Audit Scheme) in July 2019.

The main focuses of Aurubis Italia Srl are:

- Continuously improving environmental performance, in particular energy consumption and material efficiency

- Demonstrating compliance with environmental regulations with maximum transparency

- Publicly releasing its environmental strategy, environmental program, environmental management system, and key environmental performance data

- Openly engaging with interested parties (employees, local authorities, suppliers, etc.)

Environmental Protection Avellino - facts & figures

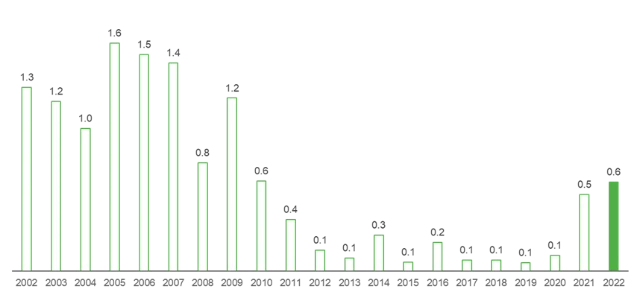

In 2011, Aurubis Italia initially installed a pilot plant followed by an inert dosing system to reduce dust and POPs. The higher dust emissions in 2021/2022 were caused by the lower efficiency of the old baghouse filters from the dust treatment system of the shaft furnace. Actions have been initiated to reduce dust emissions, and the baghouse filters were replaced in August 2022.

Dust emissions in g/t copper produced

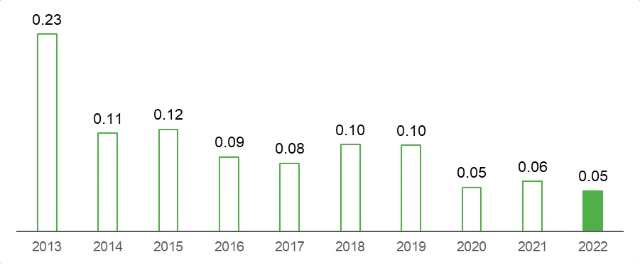

Aurubis Italia has increased the efficiency of its wastewater treatment plant.

Metal emissions to water in g/t copper produced

Environmental measures that have been implemented

Description of measure:

-

Specific treatment for casting machine cooling water installed to reduce surfactants

Date of completion:

- Completed in September 2019

Description of measure:

- EMAS registration successfully completed: IT-001951 on July 29, 2019

Date of completion:

- Completed in July 2019

Description of measure:

- Filter press system in wastewater treatment plant to reduce waste sludges

Date of completion:

- Completed in September 2020

Description of measure:

- Reduction of isopropanol consumption, direct and fugitive emissions (TVOCs, total volatile organic compounds) ducted, and fugitive emissions by refurbishing emulsion filtration system

Date of completion:

- Completed in September 2022

Description of measure:

-

Replaced with higher performance models:

a) Air heat exchanger (completed)

b) Heat recovery system for off-gas from shaft furnace (ongoing)

c) Baghouse filters (ongoing)

Date of completion:

- Completed in August 2022

Description:

- Reduced waste sludges

Status:

- Completed in September 2020

Description:

- Revamping emulsion filtration system: Reducing isopropanol consumption, TVOCs ducted, and fugitive emissions by revamping emulsion filtration system

Status:

- Completed in September 2022

Description:

- Replaced with higher performance models:

- Air heat exchanger

- Heat recovery system for off-gas from shaft furnace

- Bag house filters

Status:

- Completed in August 2022

Description:

- Aurubis Italia’s proposal approved. Waiting for the official EIA Decree

Status:

- Completed in January 2023

Current important environmental targets and measures

Status:

-

Start of feasibility study to capture off-gas from the rolling mill (containing isopropyl alcohol) as oxidation air and pass it as comburent to the burners of the shaft furnace.

-

Completion expected February 2024

Status:

- Feasibility study ongoing

- Evaluation of the next steps

Download (PDF)

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

EMAS Registration certificate (Italian)

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Environmental Statement 2024 Aurubis Italia (Italian)

PDF

3 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 14001 : 2015

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 14001 : 2015 (Italian)

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 9001 : 2015

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 45001 : 2018

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 50001 : 2018

PDF

1 MB

Gianpaolo Antonacci

Maintenance Engineering & RSPP Manager

| Phone | +39 3487069545 |