Press Release

Aurubis and COFICAB renew multi-year contract and strengthen partnership for sustainability in the automotive supply chain

Hamburg | Tuesday, October 15, 2024

- Renewed contract for stable supply of the automotive industry with high quality copper cables that are sustainably and responsibly produced

- Partners combine responsibly sourced primary copper with a substantial recycling share

- Collaboration to promote sustainability across the copper-based value chain while maintaining copper wire production of the highest quality standards

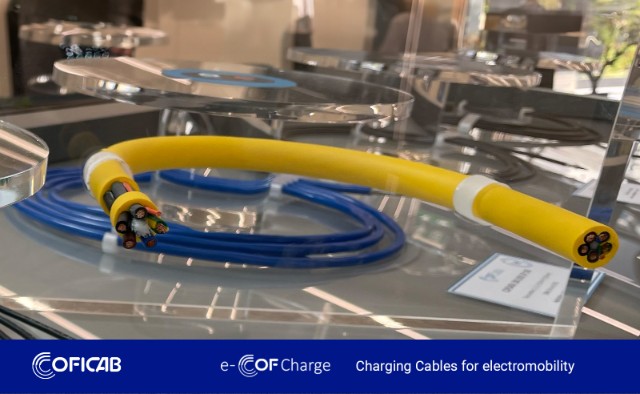

COFICAB, a global leader in the automotive industry's design, manufacturing, and sales of wires and cables, and Aurubis, a leading global provider of non-ferrous metals and one the largest copper recyclers worldwide, have renewed a multi-year contract for the supply of copper wire rod for the automotive industry. With the new contract, the two long-term partners intend to further expand sustainable volume growth in the wire and cable segment.

Sustainably sourcing copper, the backbone of electrification, is now more crucial than ever as the automotive industry races toward a greener future. Indeed, supplying the industry with copper that is sustainably and responsibly produced is the challenge of our time. Both partners combine responsibly sourced primary copper with a substantial and growing recycling share to ensure that the automotive industry continues to benefit from exceptional supply security in the future as well.

Fully understanding their position in the industry, longstanding partners Aurubis and COFICAB are intensifying their collaboration to promote sustainability across the copper-based value chain while maintaining copper wire production of the highest quality standards and process speeds. This strengthened partnership emphasizes transparency with a focus on sustainability key performance indicators in fields like CO2 footprint and the usage of recycled copper. Aurubis updates the life cycle assessments for a broad range of its products on a yearly basis as part of its transparency ambition.

Both companies share a clear objective of achieving carbon neutrality by 2050 at the latest, in line with the Paris Agreement. On the one hand, the carbon footprint of Aurubis copper cathodes has decreased by more than 40% since 2013. The carbon footprint of the copper cathode is more than 60% below the global average for all copper smelters and refiners, preventing around 4 million tons of carbon every year. Aurubis is targeting a 50% reduction in direct and indirect emissions and 24% for scope 3 emissions until 2030 compared to 2018. In addition to decarbonization, multimetal recycling is a growth focus of Aurubis.

On the other hand, COFICAB is actively advancing a dedicated sustainability roadmap, aiming for a 50% reduction in their CO2 footprint by 2030 compared to 2020 levels (scope 1, 2, and 3), while always embedding specific Original Equipment Manufacturer (OEM) requirements. To achieve such ambitious targets, COFICAB has identified several strategic focus areas, including transitioning to greener energy sources (improving its energy mix), establishing a more sustainable supply chain, enhancing its internal process efficiency, new product development, and shifting towards circularity. COFICAB notably emphasizes circularity and recycling, by developing processes to reuse internal production scrap and recycle end-of-life products.

Martin Sjoberg, SVP Commercial at Aurubis: “Aurubis produces approximately 900kt of rod in Europe – a significant amount of which is delivered to the automotive industry. This collaboration with COFICAB is yet another example of how we are developing and enhancing the transparency of the entire supply chain. COFICAB’s sustainability roadmap aligns with the pillars of the Aurubis Tomorrow Metals sustainability label. This is our promise to business partners that they will stay best in class in all the sustainability challenges of today and the future by using our metals.”

This collaboration with COFICAB is yet another example of how we are developing and enhancing the transparency of the entire supply chain.

Martin Sjöberg

Vice President Commercial

Myriam Elloumi, COFICAB’s Chief Corporate Affairs & Sustainability Officer: “As a global manufacturer of wires & cables for the automotive industry with more than 23% global market share, copper is the cornerstone of COFICAB’s operations. As we look ahead to promote sustainability and transparency throughout the supply chain, intensifying our collaboration with Aurubis will help us achieve our shared sustainable objectives. Aurubis is a company that prioritizes sustainable practices in its copper production, supported by certifications from reputable third parties. Moving forward, this collaboration marks another important step as we strengthen our sustainability efforts to meet and hopefully exceed our customers' expectations.”

Both companies actively participate in The Copper Mark, the quality seal for sustainability in the copper sector. All large smelter sites of Aurubis are fully certified by The Copper Mark. This covers more than 95% of the cathode output the company produces annually by sustainably processing concentrates and recycling materials. Furthermore, Aurubis Stolberg is the first rolling mill in the world with The Copper Mark distinction. More downstream sites are intended to follow.

Additionally, COFICAB has become a partner, committing itself to The Copper Mark’s vision and objectives, with a strong focus on integrating more sustainable copper throughout the automotive value chain. Indeed, these two companies show a strong commitment to sourcing copper in a responsible way, whether it comes from primary or recycled sources. Recycling is becoming more and more important, but as the demand for metals to fuel the green transition grows, responsibly sourced primary material will still be essential. Primary and recycling materials are both necessary.

Through enhanced transparency and by defining sustainable key performance indicators, such as CO2 footprint and recycled copper, Aurubis and COFICAB are offering the automotive supply chain solutions that facilitate progress in an environmentally conscious manner.

Downloads

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Press Release as PDF

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Portrait Martin Sjöberg

JPG

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Portrait Myriam Elloumi

JPG

1 MB

Christoph Tesch

Head of Corporate Communications

| Mobile | +49 172 4382 388 |

Meino Hauschildt

Manager Corporate Communications, Spokesperson

| Phone | +49 40 7883-3037 |