Production process - FOXROD

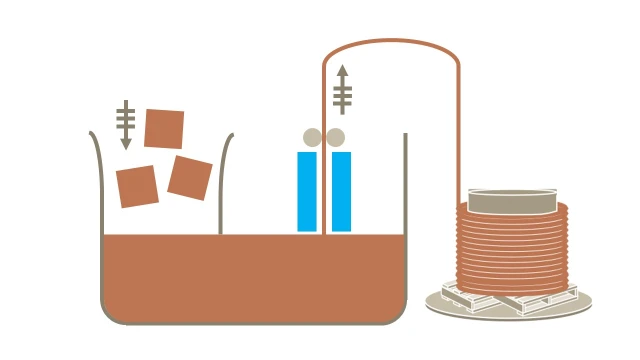

Aurubis FOXROD is produced in two plant variants: Up-Cast and Rautomead. Copper cathodes are fed into the flash smelting furnace as input material and are melted by means of induction heating. In the casting furnace, oscillating water-cooled graphite nozzles dip into the melt and withdraw the rod from the molten copper piece by piece. The copper is immediately cast to the required diameter. The production process requires no rolling whatsoever. The cast solid rod is pulled upwards and placed vertically on pallets using roller systems. One special aspect is that graphite is used to prevent air or oxygen from mixing with the molten material. Other challenges besides maintaining an oxygen content of < 4ppm are a good surface, a good microstructure and the laying of the coils. In addition, this cost-efficient, environmentally friendly production process does not involve any additional surface treatment with pickling and preservation agents or lubricants.