Environmental protection at Berango

Aurubis Berango specializes in the recovery of non-ferrous metals from a variety of material streams.

The site is situated in Berango, in the province of Biscay near Bilbao. With about 95 employees, the site focuses on complex recycling materials to produce black copper, solder, and minerals. The Berango site, formerly called Elmet, was founded in 1991. Today, the site is a frontrunner in terms of sustainability in the wider area of the entire Basque region. Building on decades of experience, the company supplies a solid base of international business partners and contributes to strengthening the circular economy.

We feel that sustainability and economic viability go hand in hand. Environmental protection as well as occupational health and safety are essential to all our processes. All employees are systematically trained in environmental protection to support environmental awareness in the workforce. Our management team ensures that all environmental aspects are considered in each process and fully integrated into operational management. The continuous improvement of our product and process designs are thus in line with our measures for ensuring environmental protection.

We regard compliance with environmental laws and regulations as a minimum requirement for our activities. Audits and inspections are conducted on a regular basis and appropriate actions are taken to continuously improve environmental protection, occupational safety and sustainability for all operations. This is also reflected in certifications such as the ISO 14001 environmental management system (since 1999), occupational health and safety in keeping with ISO 45001 (with OHSAS 18001 since 2016), and an energy management system in accordance with ISO 50001 (since 2022). All production processes are controlled using the environmental management system and incorporating occupational health and safety requirements.

By operating with specific, mostly custom-made, and high-performance technologies, we achieve exemplary success in environmental protection, while still focusing on further continuous improvement. This intensive work on continuous improvement is also reflected by the implementation of the best available techniques (BAT). Compliance with the requirements of the BAT conclusions were established and verified by the Basque government authorities in conjunction with the new environmental permit.

By operating at the highest energy efficiency levels, we are setting standards by using advanced technologies that already meet or even exceed the latest requirements.

Environmental protection Berango – facts & figures

A strong focus on dust abatement systems and dust management has always been key for the site. Since 2015, a number of projects and measures to further reduce fugitive emissions have been implemented as part of an effectiveness management system. This program includes, for example, a diffuse emission monitoring project and 3D simulation of particle movement in foundry and drying plant buildings. Moreover, the installation of a new dust extraction system will reduce dust emissions in warehouse 1.

Environmentally sound multimetal production surrounded by mountains and close to the Ría de Mundaka-Cabo de Ogoño Marine Area (~ 3.5 km north) as well as Ría del Barbadun (~ 10 km southwest) nature reserves poses environmental challenges. These require commitment that goes above and beyond legal regulations. Protecting the environment and the health of our neighbors and employees comes first and is the foundation for safeguarding the site’s future. For example, trees have been planted around the factory to make the area more environmentally friendly and more sustainable.

The noise of all production plants at the Berango site complies with the environmental permit guidelines. As a part of our noise plan, measurements for further improvement were identified for various facilities in order to further reduce noise levels and will be implemented in 2024-2025.

The site’s water demand is covered by withdrawals from a groundwater source. All of the site’s wastewater is centralized and is composed of rainwater and process wastewater. Rainwater is collected on-site and treated together with process wastewater in the wastewater treatment plant. Measures to improve water management have been implemented, such as the installation of a new water treatment plant with a higher treatment capacity, and an increased in water storage capacity through the construction of a new separate tank for fire protection. Moreover, Aurubis Berango recieved authorization for two groundwater catchments that will be developed in 2025.

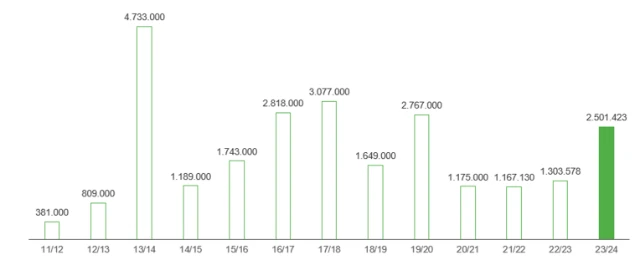

Investing in environmental protection measures is extremely important to us. Since 2012, we have invested more than € 12 million here.

The main investments have been measures for reducing fugitive emissions, noise emissions and water use. The new wastewater treatment plant together with water management improvements, better diffuse emissions monitoring, and preventing landslides have been the most important projects in recent years.

Investments in environmental protection [€]

Measures & projects

Degree of implementation/Date/Next steps:

- Measurements to further reduce the noise levels in various facilities were identified and specified in an action plan.

Status:

-

Implementation planned in fiscal year 2024-2025

Degree of implementation/Date/Next steps:

- Diffuse emission monitoring project: 3D simulation of particle movement

-

New dust extraction system (filter and suction devices)

Status:

-

Ongoing: Development of improvement action plan for foundry and drying plant buildings

- Ongoing (until September 2025)

Degree of implementation/Date/Next steps:

- New wastewater treatment plant.

- New data visualization system and KPIs in the process control system

- Two groundwater catchments

Status:

- Start: January 2023

- Ongoing (until June 2025)

- Ongoing (until September 2025)

Degree of implementation:

- Implementation of measures to prevent landslides in various areas

Status:

- Completed

Degree of implementation:

- Implementation of measures to prevent landslides in various areas

Status:

- Completed

Certificates Berango

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 9001: 2015

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 14001: 2015

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 45001: 2018

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

OHSAS 18001: 2017

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Authorized Economic Operator (AEO - Certificate)

PDF

1 MB

Silvia Corulla

Sustainable Development Department

| Phone | +34 94 66 89 113 |